Why steel?

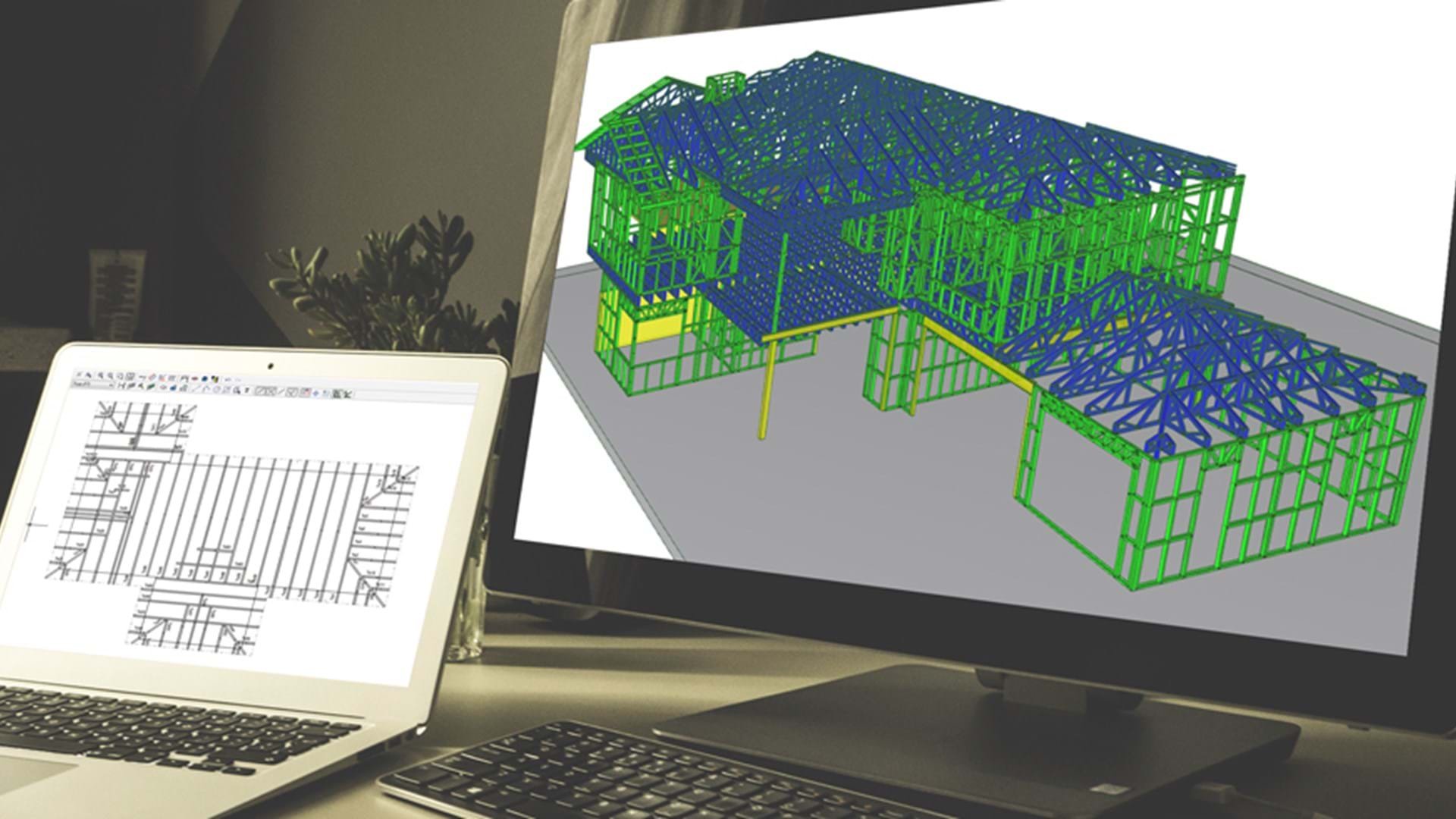

The process.

Building Better with Steel.

Durability - Steel is dimensionally stable and does not expand or contract with changes in moisture content.

High Tensile Strength - Steel infrastructure will also never warp, keeping the surface level.

Time Efficient - Manufacturing to erection can take as little as two days.

Cost Savings - Lower labor costs, less waste, quicker turnaround time, insurance savings and competitive material costs compared to alternative building materials

Non-Combustible - Steel-frame buildings are shown to better withstand forces of nature such as earthquakes, high winds, heavy snow, and hurricanes than do those with wood framing.

Mold Free - Steel is resistant to mold, which means benefits to both the builder and homeowner.

Longevity - The lifespan for steel framing with exterior exposures in higher humidity and external pollutants is estimated to be 150 years or more.

Pest Free - Termites and other pests cannot burrow into the steel beams making infestations less likely and cheaper to treat.

MANUFACTURE & PANELIZATION STAGE CFS

They can be produced in large quantities and at high speed with consistent quality and precision.

The wide range of advanced tooling functions provided by systems like the FRAMECAD System allow high productivity and versatile output to produce roof trusses, wall frames, and floor joists — all to exact measurements, saving time and costly wastage in the construction stage. Detailed design speeds up compliance, reduces engineering cost and minimizes room for error on-site.

CONSTRUCTION PHASE

CFS fabricators supply frames pre-assembled, strong and straight, and clearly identifiable. No on-site welding or cutting is normally required. This means that the erection process is fast and simple – requiring less labor time on-site and heavy-lifting equipment.

Steel frames do not absorb moisture so there is no delay waiting for frames to dry. This means minimized weather delays for rain, snow, or excessive heat, for example.

CFS construction can offer a much more predictable construction schedule and less on-site cost than traditional construction methods. For example, as the material is lightweight, no heavy lifting equipment is needed on-site, frames, trusses and joists can typically be carried into place by on-site labor.

Frames are made to precise dimensions meaning pre-made windows, doors and bathrooms will fit perfectly and quickly reducing engineering cost and minimizing room for error on-site.

Contact Us

If you require any further information, feel free to contact us.